Address: 563 Nui Thanh, Hoa Cuong Ward, Da Nang City

Tel: 0916.860.231 - 0905.160.231 - Website: davitecco.com - Email: info@davitecco.com

Warehouse: Thach Nham Dong Village, Ba Na Commune, Da Nang City

Promotion price Contact

Condition of productsIn stock

Cast iron globe valve is a specialized valve line to open or close or adjust the amount of fluid passing through the valve. Valves are often used in all kinds of media such as: Hot oil, compressed air, superheated steam, saturated steam, hot water, gas...

Cast iron globe valve is the most popular ball valve on the market today. This is a specialized valve line used to open and close and regulate the flow of fluid in the pipeline system. So what is a cast iron globe valve? How is the valve constructed? What is the application of the valve? We invite you to find out through this article below.

Cast iron globe valve | Taiwan- Korea | Good price.

1. Introduction of cast iron globe valve.

Cast iron globe valve is a type of globe valve made from cast iron, ductile iron, cast iron, gray cast iron, white cast iron, spherical cast iron,... This is a specialized valve line for regulating, opening and closing the flow of fluid flows. allow them to pass through or prevent them from passing through piping systems. The valve is composed of a body made of cast iron and a steering wheel (handwheel).

The cast iron ball valve has a high carbon content that helps the valve structure to be durable and sturdy, so the valve can be applied in many industries and fields related to water, clean water, wastewater treatment systems, Liquids, chemicals, gases, vapor systems...

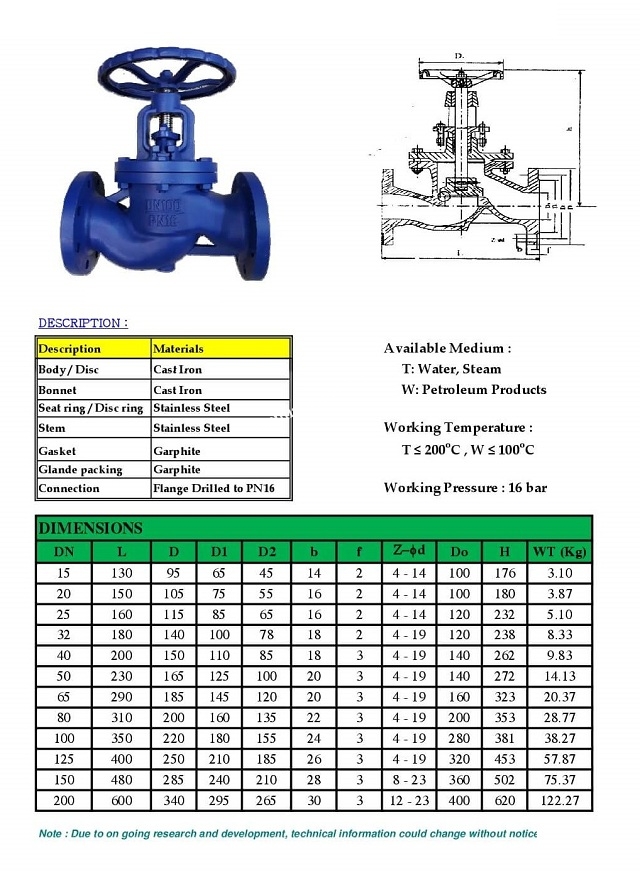

Cast iron saddle ball valve is connected to the pipeline system by thread or flange mounting with sizes from DN15, DN20, DN25, DN32, DN40, DN50, DN65, DN80, DN100, DN125, DN150, DN200, D250, DN300, DN350…In stock, 12 months warranty, competitive price.

2. Cast iron globe valve structure.

The cast iron S-ball valve is composed of the following main parts:

Valve body:

The valve body is in the shape of a fall or saddle. Constructed of ductile iron, with 2 connection types, threaded and flanged, where the fluid flows directly through the valve.

Valve cover:

Is a monolithic molded part along with the valve body material. Connected to the valve body by bolts.

Valve shaft:

The part that connects the valve disc to the steering wheel. Made of hard alloy to increase impact resistance from fluid flows through the valve. The valve disc acts as a door for or prevents the

Valve disc:

Parts that are in direct contact with the fluid. The valve disc has a cork or cone shape, which is combined with the valve shaft to form a lifting mechanism. Valve discs are made from highly corrosion resistant hard alloys.

Sealing gasket:

This is the part that helps keep substances from leaking out of the valve, creating tightness for the valve.

Steering wheel (hand crank):

This is the part used to control the opening and closing of the cast iron globe valve.

3. General specifications of cast iron globe valve

Origin: Korea, Taiwan, Japan, China

Availability: Available in all sizes

Warranty 12 months.

* Catalog of cast iron globe valves.

4. Working principle of cast iron globe valve.

When we control the steering wheel of the valve, the valve disc will be raised or lowered from the original position. Depending on the type of globe valve, the disc can be machined into many different shapes. By changing the shape of the disc, the flow rate when opening the valve changes significantly.

When the valve disc is in the sealing position, the septum between the two halves in the valve body is equivalent to the closed state of the valve. When operating the handwheel control, the steering wheel will act on the valve stem to lift the valve disc out of the baffle position, allowing the fluid to pass through the gap above the baffle equivalent to the fully open state of the valve.

5.Advantages and disadvantages of cast iron globe valves.

5.1. Advantage.

Is a valve line with good flow regulation, easy to use

When operating regularly, the cast iron globe valve has high durability, is less susceptible to corrosion and damage because when opened, the valve disc is not in contact with the fluid.

Globe valves have a high degree of tightness, so they are less prone to leakage than other valves.

Fast opening and closing time due to shorter stroke than gate valve

5.2. Defect.

Pressure through the valve is reduced because the fluid passing through the valve is diverted

Weight is larger than other valves of the same size and pressure.

The cost is relatively higher than other valves.

6. Applications of cast iron globe valves.

Globe valves are used in systems where flow control is required and leak tightness is also important. With its preeminent features, cast iron steam globe valves are often used in the following systems:

Above are our shares about the cast iron ball valve line. Currently, this product line is available in our warehouse with a full

Promotion

Other products

Specializing in Mineral wool products, Rockwool, Glass wool, Insulation products, Vulcanized rubber, Soundproofing products, Refractory brick products, Industrial ventilation, Valves and pipe fittings, Copper pipes & copper pipe fittings, Burners & burner accessories

Currently, the price of Ceramic fiber in sheet form is a topic that many people ...